High-Capacity line 1

EKRA 4000 series Compact

EKRA 4000 series Compact

- Print sizes up to 610x510 mm

- Easy to operate thanks to the SIMPLEX user interface

- The cycle time: 9.11 s + print

- Suitable for sizes up to 31 inch templates

- IPAG Jet dispensation glue

- Applied solder paste inspection 2.5D

- Accuracy in regards to process repeatability

Assembleon AX-301

Assembleon AX-301

- Capacity 33 000 – 66 000 SMD components per hour

- An advanced collision detection system

- Precisely defined pressure during pick and placement ( FORCE CONTROL)=no damage to components

- Min. component size – 0.4 x 0.2 mm (01005)

- Capacity can be increased according to need without interfering with the fixture lines: Capacity as required

Assembleon MG-1R

Assembleon MG-1R

- Eight-headed pick and placement automatic machine

- Capacity up to 24 000 components per hour

- Controlled heads for accurate placement of components

- Precision of pick and placement 50 um of chip components, 30 um BGA

- Stations for automatic nozzle cleaning

- Automatic temperature feedback for expansion due to temperature control

SMT QuattroPeak

SMT QuattroPeak

- 3 pre-heating zones

- 2 re-melting zones with 4 thermal modules (2 top and 2 bottom)

- Thermal profiles setting

- Reliable soldering of components with high heat dissipation

- Roller conveyor with center support (programmable speed)

High-Capacity line 2

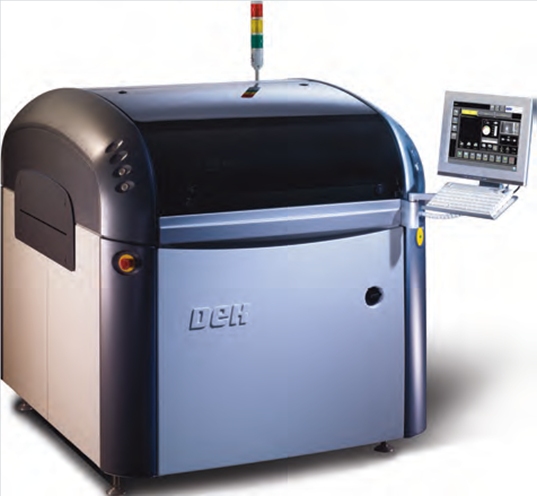

DEK HORIZON 03iX

- 2D Optical quality control of paste application HawkEye 750

- Printable Area max. 600x508 mm

- Accuracy of 12.5 um (6 sigma)

- Templates already 29x29 inches

- Process-driven PC – LCD touch-screen with a menu in CZ/EN

- Programmable template cleaning

- 2D scanner

Yamaha YS24

Yamaha YS24

- Sizes of PCB: min. length 50× width 50mm – max. length 700 x width 460mm

- Capacity: 72000 CPH

- Pick and placement accuracy: ± 0.05 mm (? 3 +?) ± 0.03 mm (3?)

- Size of components: 0402 – 32 mm MAX

- Dispensers parts: for 120 types

Yamaha YG100R

Yamaha YG100R

- Eight-headed pick and placement automatic machine

- Capacity up to 24 000 parts per hour

- Controlled heads for exact positioning of components

- Precision pick and placement of 50 um of a chip component, BGA 30 um

- Mounts components 01005 – 100 x 45 mm

- Stations for automatic nozzle cleaning

- Automatic temperature feedback for expansion due to temperature control

Seho PowerReflow 2

Seho PowerReflow 2

- 6 pre-heating zones

- 3 reflow zones

- Thermal profiles setting

- Total length 2735 mm

- Soldering in normal and nitrogen atmosphere

- Controlled active cooling

- Easy to use software

Line 3

L3 DEK HORIZON 03iX

L3 DEK HORIZON 03iX

- 2D Optical quality control of paste application HawkEye 750

- Precision 12,5um (6 sigma)

- Templates already 29 x 29 inches

- Process-driven PC – LCD touch-screen with a menu in CZ/EN

- Programmable cleaning template

- 2D scanner

Assembleon MG-1R

Assembleon MG-1R

- Eight-headed pick and placement automatic machine

- Capacity up to 24,000 components per hour

- Controlled heads for exact positioning of components

- Precision of pick and placement of 50 um of chip components, BGA 30 um

- Mounts components 01005 – 100 x 45 mm

- Stations for automatic nozzle cleaning

.

SMT 2.8 TC

SMT 2.8 TC

- 3 pre-heating zones

- 1 re-melting zone

- Thermal profiles setting

- Belt conveyor (programmable speed)

Others

Washing equipment INJET CDR-388

Washing equipment INJET CDR-388

- Fully automatic processes for washing, rinsing and drying – all in one chamber

- Frame, storage tubs, pipes, cladding – made completely out of stainless steel

- Complete PLC

- Automatic measurement of the quality of Di-water

.jpg) Screen printing Autotronik SP 1200

Screen printing Autotronik SP 1200

- Automatic printing device with camera centering

- Centering repeatability +/- 0,01 mm

- The print area 1200x400 mm

- Vacuum table for PCB up to 1000 mm

Laser INSIGNIUM 3000

- Direct laser marking PCB

- Marking PCB to the dimensions of 508 x 508 mm

- Setting up PCB using the feed conveyor

- The servo-driven axis system