3D INLINE AOI

- Real 3D measurement of the surface of the PCB and its automatic evaluation

- A new dimension, where the clear indicator of quality of PCB assembly is a precisely measured surface with an unambiguous interpretation of measurements, and not a mere processing of 2D image using various algorithms

- AOI thus moves into the category of measuring equipment with the ability to automatically identify defects that are not detectable for common 2D systems.

- Resolution 15um

- 4 moire projection

- 4MPx high-speed camera

- Option of dual lane operation

3D SPI 8030-2

- SPI designed for common SMT production

- Online operation

- Resolution from 20 to 25um

- 2 moiré projections

- 4 MPx camera

- Inspection speed 0,45 sec/frame

Digital Microscope Vision Z2

- FULL HD camera with a resolution of 1920x1080px

- Magnification 1.8x – 50x (digitally up to 122x)

- Storing photo images via USB

- Working distance 250 mm

- Large field of view– up to 295 mm

- Automatic or manual treatment

- Adjustable LED lighting

- Image transmission to LCD through HDMI

- Robust stand with mounting

- Optional – external controller

Automated Optical Inspection Mirtec MV – 2HTL

Automated Optical Inspection Mirtec MV – 2HTL

- Detects soldering errors, reversed parts, missing parts, misplaced components, short circuits between the solder joints, checks SMD and thru-hole components

- 1,3Mpix camera

- Ability to store photos of found defects

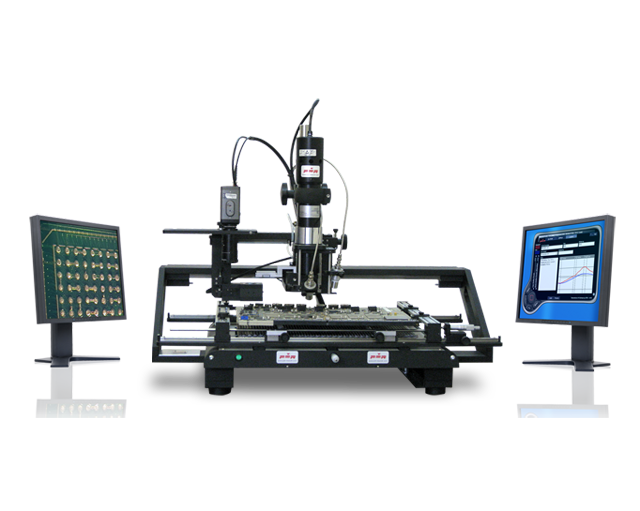

Relay station IR- X410V i

i

- Station for re-soldering of components in BGA housings

- Soldering is not performed by IR technologies

- Adjusting the course of warm up via PC

- Thanks to the technology of image overlap, the exact molding of BGA slots on PCB is possible

X-ray YXLON Y.Cougar

- Fast 2D and 3D microinspection

- Resolution < 1 um

- High speed flat-panel digital detector

- An open type of X-ray tube

- Product size: 440×550 mm

Monitoring system MANTIS

- Clear, undistorted, three-dimensional, colour and positionally accurately magnified.

Automated Optical

Inspection Mirtec MV-3 Series

- Detects soldering errors, reversed parts, missing parts, misplaced components, short circuits between the solder joints, checks SMD and thru-hole components

- Checks solder joints in the color spectrum

- 10 Mpix camera with a telecentric lens and 4 side cameras

- Laser measuring the height of components (BGA)

- Ability to store photos of found defects (SPC)

- Cycle time 11 sec

Automated Optical

Inspection Mirtec MV-3L

- Detects soldering errors, reversed parts, missing parts, misplaced components, short circuits between the solder joints, checks SMD and thru-hole components

- 5 Mpix camera with a telecentric lens and 4 side cameras

- Laser measuring the height of components (BGA)

- Ability to store photos of found defects (SPC)